This test is a long time coming. A couple years ago at CLA, Steve Chapman and I were looking over a flint gun made by Allan Sandy. The vent Allan used had two smaller holes located horizontally. Allan said the vent was internally coned but used two .052″ holes. Allan said he didn’t know whether it was faster or slower than a normal vent. My reply was that I could time it. Allan offered to provide me a vent, and on the way home, Steve and I planned how the vent would be tested.

Time passed with many interruptions in the way. In the meantime Fred Stutzenberger entered the picture. I believe Fred saw the “double-hole vent” on Sandy’s table at the same show that we did. Fred however, was more prompt than we were and published an article on the vent in the August 2014 issue of MuzzleBlasts.

Without great detail, Fred’s article compared Allan’s double-hole vent with a single-hole vent that had the same area as the sum of the two smaller vents. His findings showed that shots fired with the double-hole vent had slightly higher velocities than the single-hole vent even, though the vent area was the same. The “choked-flow principle” (comparing circumference to area) is the likely cause. Fred explains this better than I do; please read the article.

Our testing focused only on ignition speeds. We compared ignition time of the double-hole vent (two .052″ holes) and the single-hole vent (.073″) Both vents have the same area, but vary in their circumferences.

The main question I have is, “If the choked flow principle tends to restrict flow leaving the vent, might it also restrict flow entering the vent, causing slower ignition?”

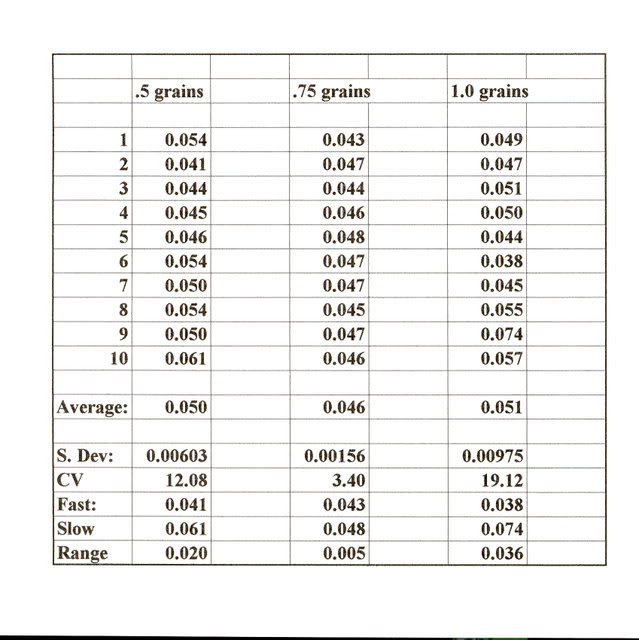

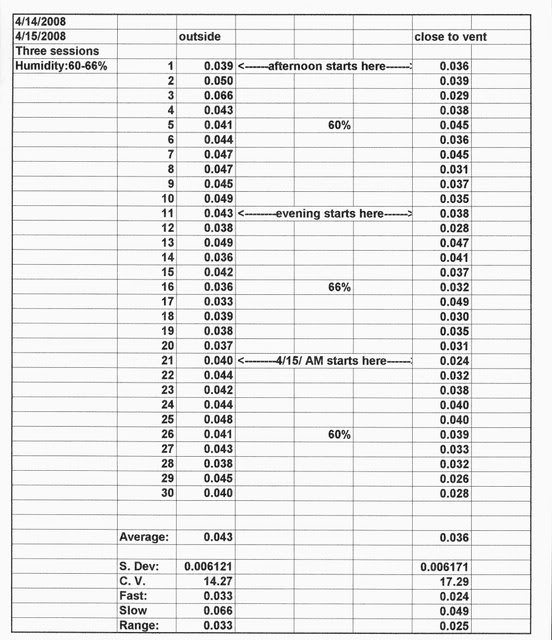

We used a 10″ barrel stub with a small Siler flint. The test used a double-hole vent with .052 holes and a single-hole vent with a .073 hole. We did 10 trials each and lit the pan with a red hot copper wire. Our reason for this was to prevent a changing flint edge from entering into the test. The single .073 vent was better both in speed and consistency.

Before finishing, we ran 5 trials each in which the pan was ignited by the small Siler. In those trials the single-hole vent was better, but by a smaller margin. None of the trials sounded abnormal to the ear. No matter the range from high to low, human senses could not tell the difference. In fact, Steve tried to guess and was invariably wrong.

Interpreting the results can sometimes be misleading. In this case, I like the single-hole vent. However, I do have two doubts. (1) I have questions about the reliability of a vent as small as .052”. A double-hole vent with larger holes might alter the result. (2) I wonder if the shape of vent’s exterior would change the result.

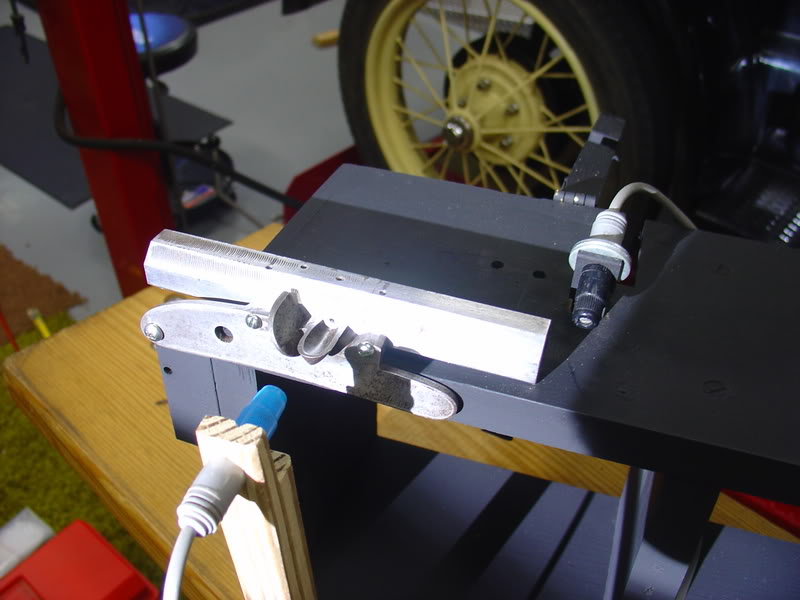

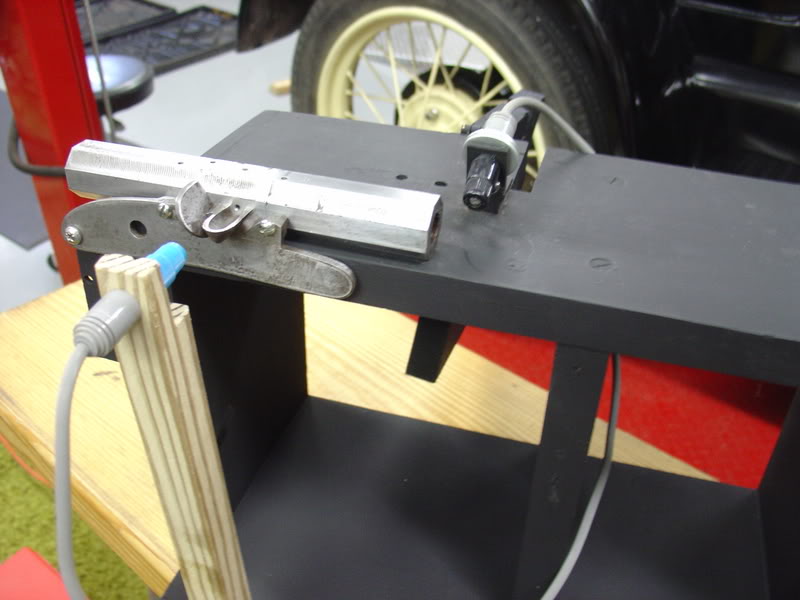

The included photos show the fixture and the position of the photo cells used in the timing. The photo cell at the pan trigger the start, while the photo cell and the muzzle triggers the stop.

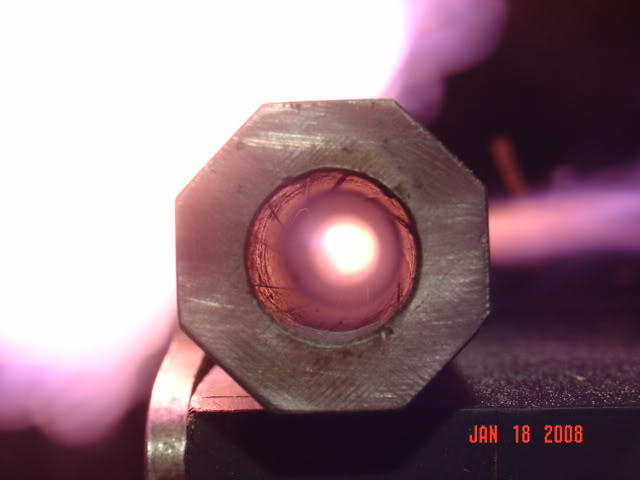

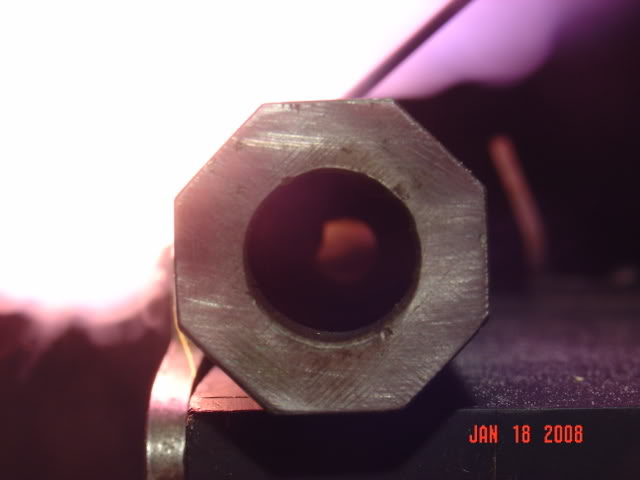

The last pic is a close up of the vent. These holes are .052″. BTW, the stock is a heavily mutilated factory second supplied by Jim Chambers. It was important because it allowed the sear to be struck from below by the plunger. It also allowed us to use a small Siler lock for an earlier test. At that time it allowed three different locks to be tested using the same lock mortice.

To conclude, I’d like to thank Allan Sandy for the chance to time his vent. I feel that this vent type is well worth studying. I’d like to repeat this with a .055” 2 hole vent.

My thanks also to Steve Chapman and Mike Coggeshall for their assistance in the testing.

Larry Pletcher, editor