[box type=”note” align=”aligncenter” ]Reprinted from MuzzleBlasts December 1992 by Larry Pletcher —- This article is the third in a series of three reprinted articles that measure a flintlock’s ability to ignite black powder. This article deals experimental Siler flintlock components from Jim Chambers, riflemaker and vendor of black powder parts.[/box]

Most of us, at one time or another, have wondered what factors cause locks to produce good results. Obviously, there are considerations which we have not been able to measure and maybe can never isolate. In this article, I would like to look at some factors

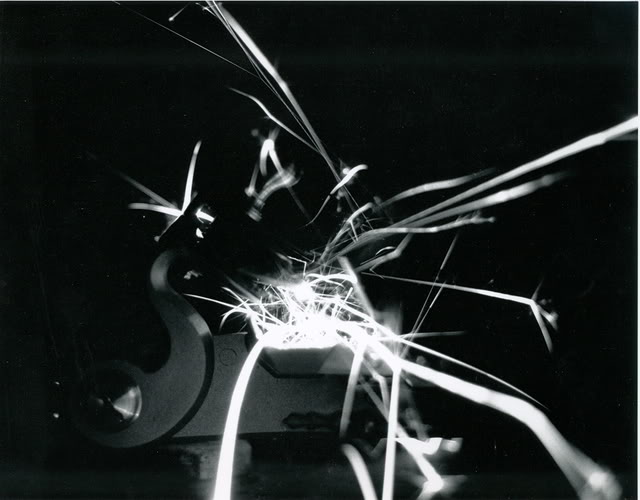

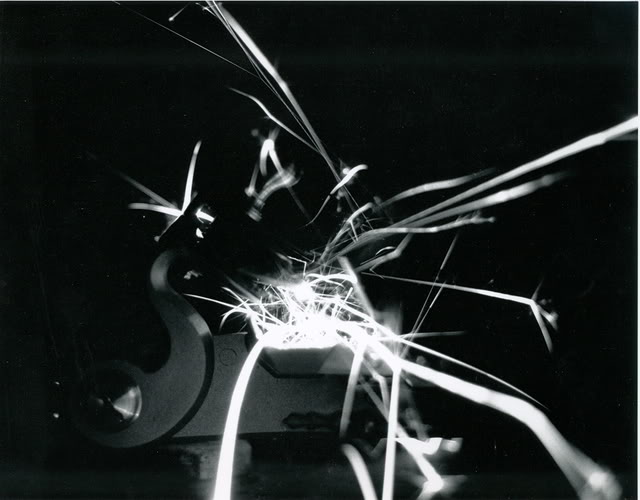

Photo 1: The flint is just about to begin contact with the frizzen. Two thirds of the mechanical time is complete.

which have not yet been measured. By experimenting with different modifications, perhaps we can identify some characteristics of successful locks.

This month’s experiment was done with the help of Jim Chambers. He supplied me with a large Siler lock with replaceable tumblers and cocks. This gave me a chance to alter one variable at a time to see what change it would make. I was provided with the following:

a Siler lock assembled by Mr. Chambers

a stock Siler tumbler

a modified Siler tumbler

a Chambers tumbler

a stock Siler cock

a Chambers cock

(The mainspring needed to be repositioned depending on which tumbler was installed. Mr. Chambers modified the lockplate allowing this change to be made easily).

With these parts to use, six possible combinations could be tested. I began by testing to see which way the flint bevel should be placed to work the best. The flint installed with the bevel up provided the best performance. Each test thereafter was done this way.

Photo 2: This photo was taken .002 seconds later than Photo 1.

Photo 3: This photo was taken .002 seconds after the previous one. The flint fragment located just below the flint in the photo demonstrates a variable always present – a constantly changing flint edge.

As in earlier articles, testing was done with a measured amount of Goex 4Fg powder. (The powder had been stored at room temperature in a dry environment). The flint and frizzen were cleaned between trials. Flints were knapped when any noticeable change in operation developed.

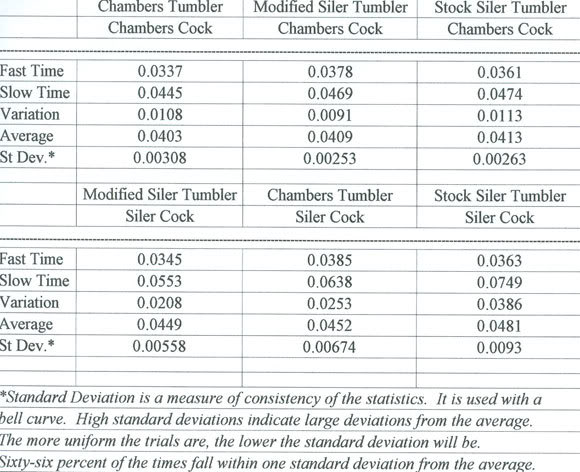

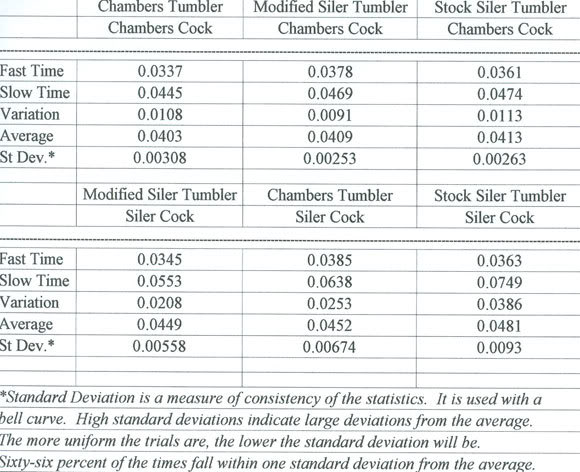

A series of 20 trials were conducted with each possible combination. The following chart provide a summary of trials:

An examination of the charts leads to a number of conclusions. First of all, the modified Siler tumber (test 2,4) had a pronounced camming effect as the lock was brought to full cock. In fact, one had to practice finding the half cock notch. The Chambers tumbler had a camming effect to a lesser degree; the stock Siler tumbler had none. Since the difference in results 1,2,3 were so small, the camming effect may not add a great deal to the functioning of the lock.

The Chambers cock seems to make a difference in the speed and standard deviation in these tests. Wile the tumbler does make a small difference, the first three combinations (in both speed and standard deviation) used the Chamber cock. This

cock had a lightly longer throw than the Siler cock. The extra length seems to be achieved by lengthening the neck; the angle of the jaws of the cock does not appear to have been changed. Whatever the difference, the Chambers cock appears to be an improvement. If I were buying a lock from Jim Chambers, I would specify the modified tumbler and Chambers cock.

The standard deviation in each combination seems to increase as the time increases. (Tests 1 and 2 were the only ones which did not follow that pattern). The standard deviation on tests 2 and 3 were very good. They would compare favorably with most locks today.

In June of 1990, I attended the NMLRA’s Gunsmithing Workshop & Seminar held at Northern Kentucky University. One topic discussed dealt with position of sparks when a flintlock is fired. One instructor proved to us, using ultra high speed video, that sparks from a well-made lock literally coat the pan! Photo Number 4 demonstrates this phenomenon quite well. This photo is illuminated only by sparks produced by the lock. Note that the pan is white with sparks.

Photo 4: Taken without any flash, this photo is lit only by sparks. It is safe to say that this lock puts the sparks in the right place.

Another spark phenomenon discussed was a secondary burst. The spark appears to fly away only to burst into three or four new sparks. This can be seen in two of the photos.

Measurements from the photos can be used to determine the speed of the flint as it travels down the frizzen. Using photos 2 and 3, I measured the distance traveled during the .002 seconds that elapsed. I set up a proportion to convert distance to the scale of the lock. This gave a flint speed of 24.2 feet per second. By measuring other locks in the same way, perhaps we can determine how much effect flint speed has on spark production.

As I have stated before in other articles, I think we are just scratching the surface in learning what makes locks work well. There is much to learn. As before, suggestions are welcome and may be sent to 4595 E. Woodland Acres, Syracuse, IN 46567.