In my earlier article called “Pan Vent Experiments”, I examined powder placement in the pan and timed vent locations. I found that pan placement was far more forgiving that we thought. I found that a vent covered with prime did NOT slow ignition as we once thought. In fact priming powder located as close as possible to the barrel was the fastest way to prime. In this photo article, I will look at the possibility that a vent can be placed too high.

The series of photos included here are in response to comments generated in a number of internet forums the author reads. I have timed low, level, and high vent locations and found no significant difference in ignition times. Questions still surface about the preferred location of the vent. Until these ignition tests and these photos, all we had to go by was human senses. The best gun makers in the world early or modern had no better tools of discovery. Decisions they made were made without the benefit of an ability to test their theories. If the performance of the flintlock passed their “human sense test”, it was deemed correct. Now we can actually review their decisions about vent placement with test results they never had.

All earlier photos that I took were with the vent in the “level” position. The purpose of those photos was to examine other variables. Here the only variable will be the height of the vent. I took three photos at each of the following vent locations:

a. vent located .030” above the top level of the pan

b. vent located level with the top of the pan

c. vent in the bottom of the pan

The reason for multiple photos is that I hated basing any conclusion on only one trial. I set the camera to look into the muzzle. The aperture was f13 and the shutter held the lens open for 4 seconds. A cable release was used to make the operation easier. I primed the pan with the powder as close as possible to the barrel. Earlier tests showed this to be anywhere from 15-25% faster. In the low vent position the prime covered the vent. This is of no concern – contrary to popular belief, this does NOT result in slower times.

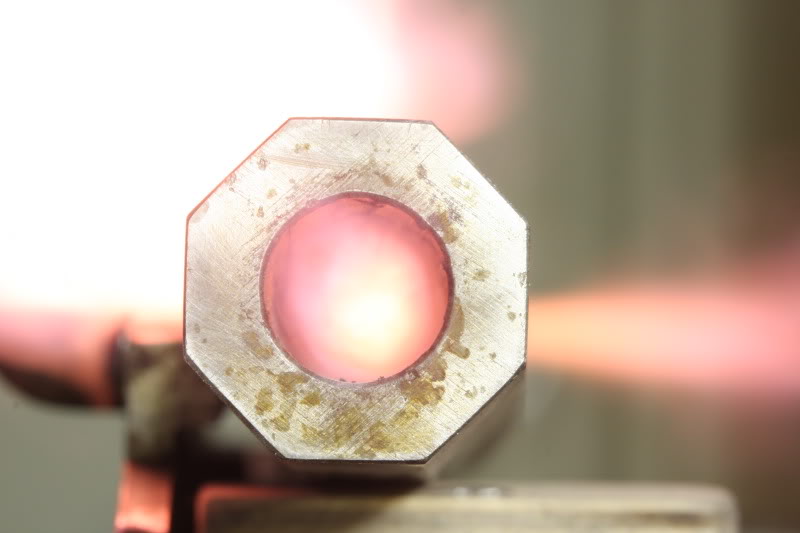

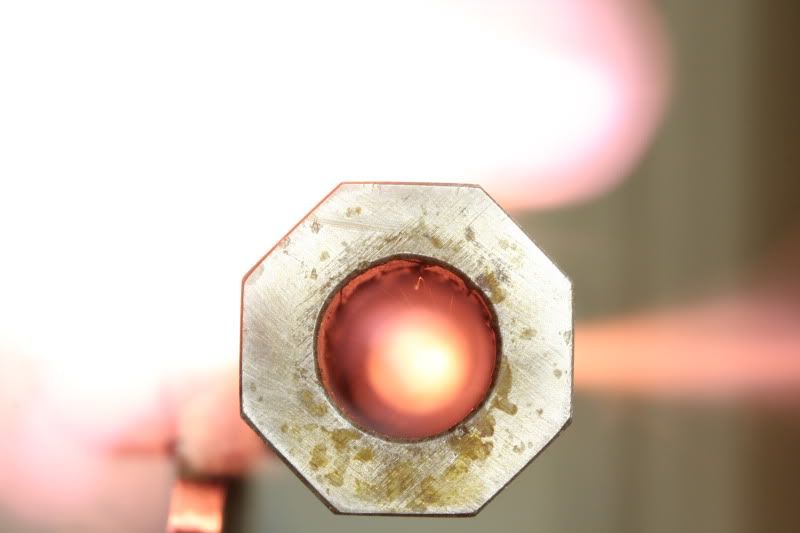

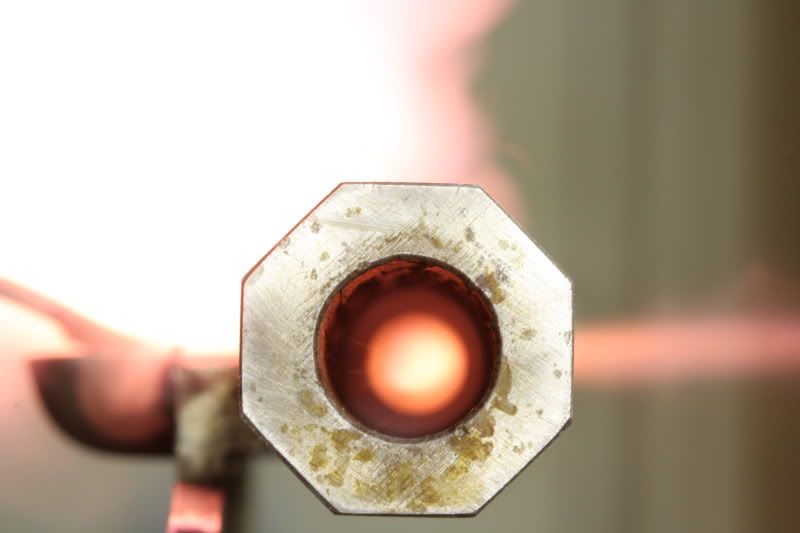

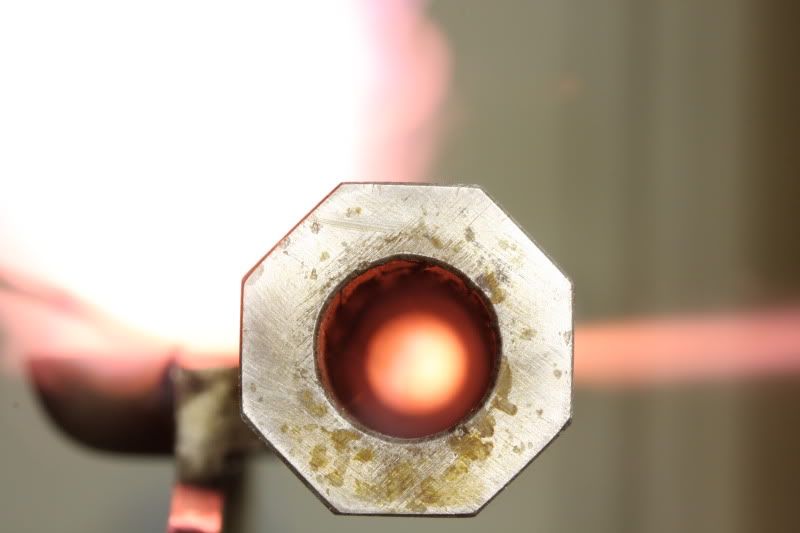

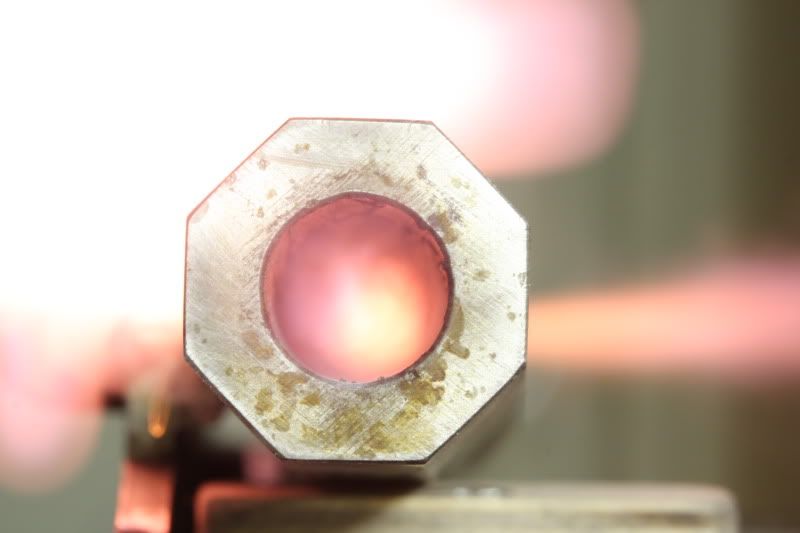

The vent locations were photographed three times with 1/2 grain of Swiss and ¾ grain of Swiss. These charges were weighted. The results of the different amounts of powder were very similar. I chose to upload the ¾ grain photos. Here are the photos of the vent .030” above level with the pan top:

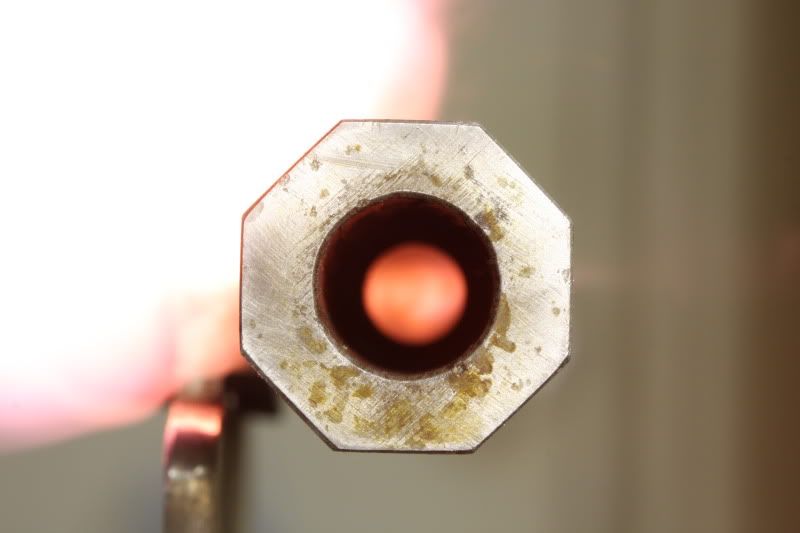

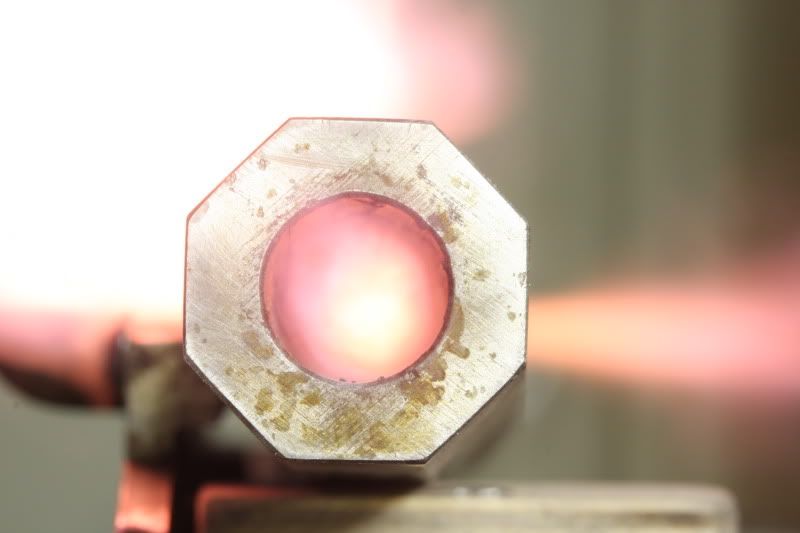

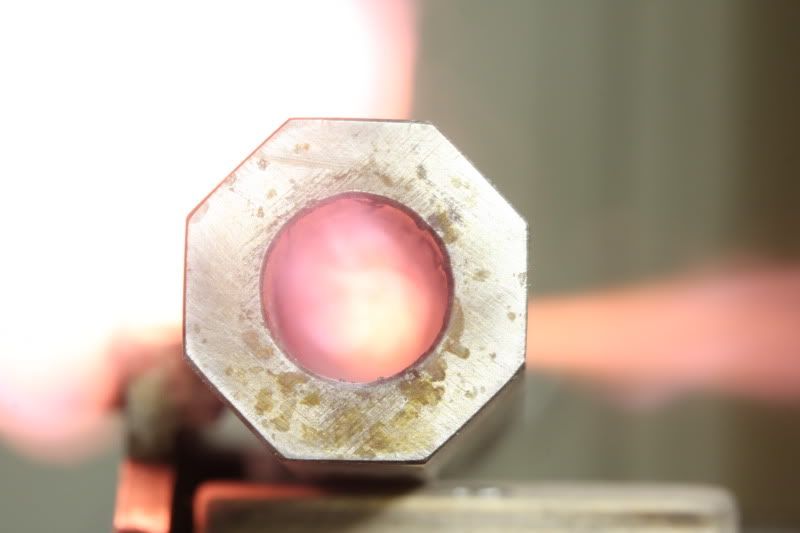

Here are the photos with the vent level with the pan top:

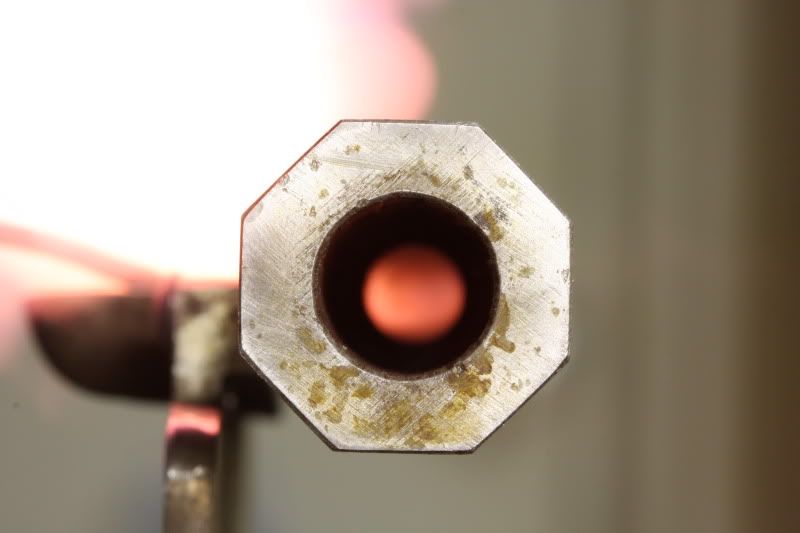

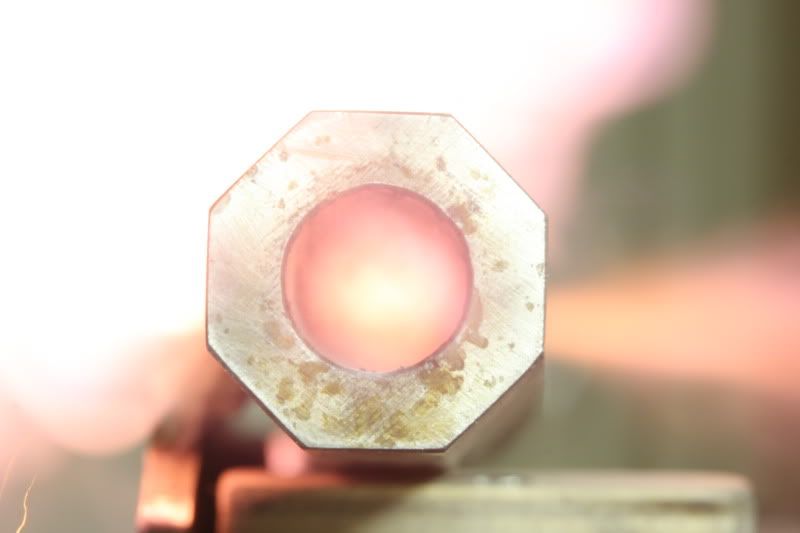

Here are the photos taken with the vent at the bottom of the pan:

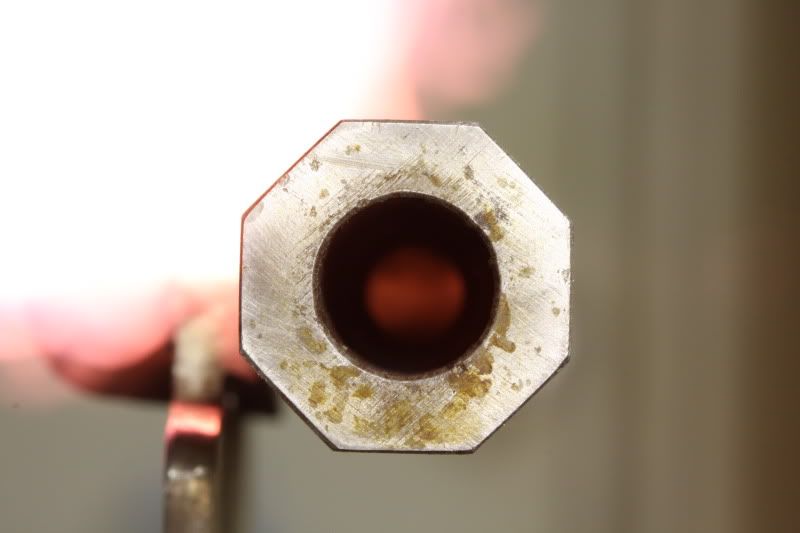

One additional photo was taken because most shooters use more priming powder that the ¾ grain used in this test. My pan charger is advertized to throw 3 grains. I used it for this final trial in the low vent position:

Conclusions drawn here are based on these photos and the data collected in the earlier article. A strong argument can be made for the level vent location used by the majority of flint makers. Numerical data supports this, and these photos show a strong flame moving through the vent. My rifles use this location and I see no advantage in changing them.

An equally strong argument can be made for the low vent location. The photo evidence also shows an impressive flame front to go along with good timing numbers. If my rifle had a low vent, I would not change it.

I question the location tested here with the vent located .030″ higher than the top of the pan. The flame traveling through the vent is noticably less than the the other positions. I timed a high vent position earlier, but I did not specifically set the vent to the 030″ position photographed here. Since high vent data gathered earlier was not precisely placed, it may not be valid here. Based on the weak flame seen inside the barrel, I tend to conclude that .030″ may be too high for best ignition.

Leave a Reply

You must be logged in to post a comment.